What’s Wrong with Bananas

Reproductively, domesticated banana plants are self-copying machines. Proto-farmers who found an individual whose fruit they liked (maybe tasty and not so seedy) could dig up its suckers and replant them in a nearby clearing or even along the trail. In a few years, an industrious proto-farmer might have had reproduced dozens of plants of that genet.

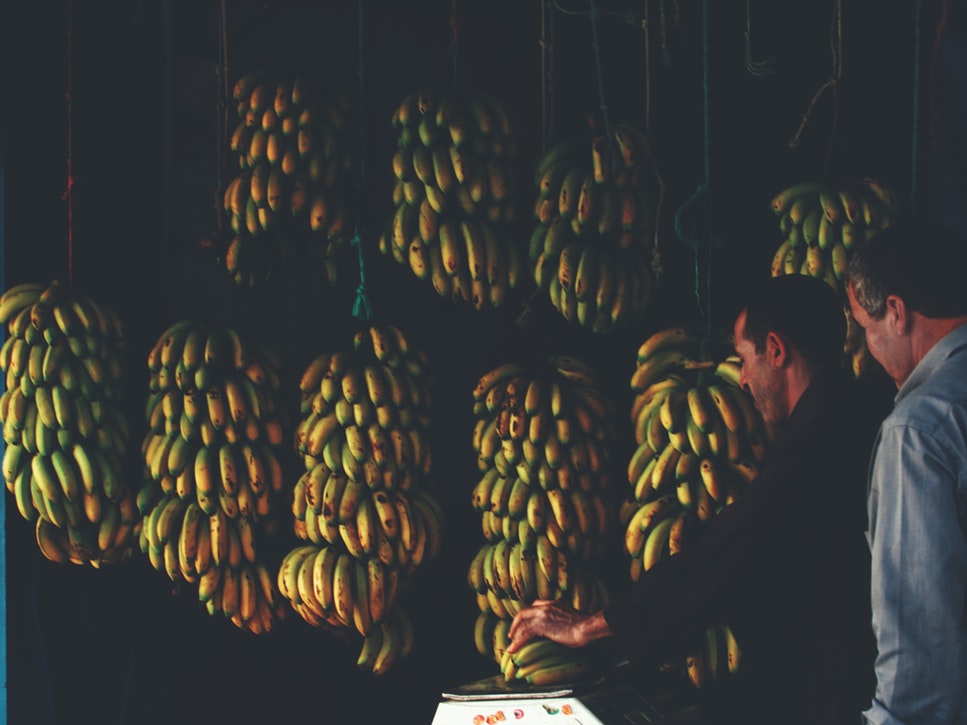

Skip ahead a few thousand years. During the Age of Discovery and Conquest, that model took on global proportions as plant explorers transported a relatively small number of favorite clones out of Southeast Asia and introduced them to the plantation agriculture of tropical colonies. With the emergence of the 20th century, the confluence of the Industrial Revolution with plantation agriculture led to the propagation of a single globally favored banana genet (descended from a single instance of sperm-egg fusion) for export from the tropics to waiting markets in the industrial north. Foreshadowing the uniform and reliable vehicle of Henry Ford, the banana industry had found the uniform and reliable banana clone. Everyone was eating the Gros Michel banana (aka Big Mike).

If you ask any long-term restaurateur, you will find that the secret to getting customers to come back again and again depends on making their favorite meal exactly the same again and again.1 Constant change—for example, a port-cherry sauce on the duck this week and a lime-dill sauce the next—will send patrons scurrying. If the newspaper food critic’s blog tells you to try the tempeh, you won’t be pleased to hear that it was replaced by tofu. Part of fast food’s global success is that you pretty much know what you are getting. A McDonald’s burger and fries meal hardly varies from Riverside, California, to Elk Grove, Illinois, to Uppsala, Sweden. (Actually, McDonald’s fries in Sweden are a pleasant surprise.) We are especially dismayed by nasty shocks such as the apricot that never ripens properly or the clementine mandarin with a dozen seeds.

From farmer to grocer, the whole modern industrial food production and delivery stream depends on predictable uniformity. For field crops, seeds must germinate at the same time, and plants must grow uniformly. Grain must mature uniformly so that a farmhand swinging a scythe or driving a combine can harvest a field in a single sweep. For horticultural crops, packing lines work best when fruits have predictable shapes and sizes to be sorted into standardized boxes. Retailers don’t like it when some fruits arrive ripe, others are immature, and the rest are rotten. Given a choice, most customers will leave the oddly shaped tomato or the unevenly colored orange in the bin.

The major sources of biological variation are environmental differences and genetic differences. Industrial farmers have become increasingly sophisticated in dealing with environmental variation. The cutting edge known as precision agriculture enables a farmer to treat every plant as uniformly as possible. Combining precise spatial information from a Global Positioning System (GPS) with high-tech field machinery can be used to alter the external environment (flatten that field). Add soil and plant sensors for nutrient and water status, mix with Internet cloud-based data analytic tools, and you’ve got a recipe for undoing some of Mother Nature’s environmental tweaks.